OEM & ODM

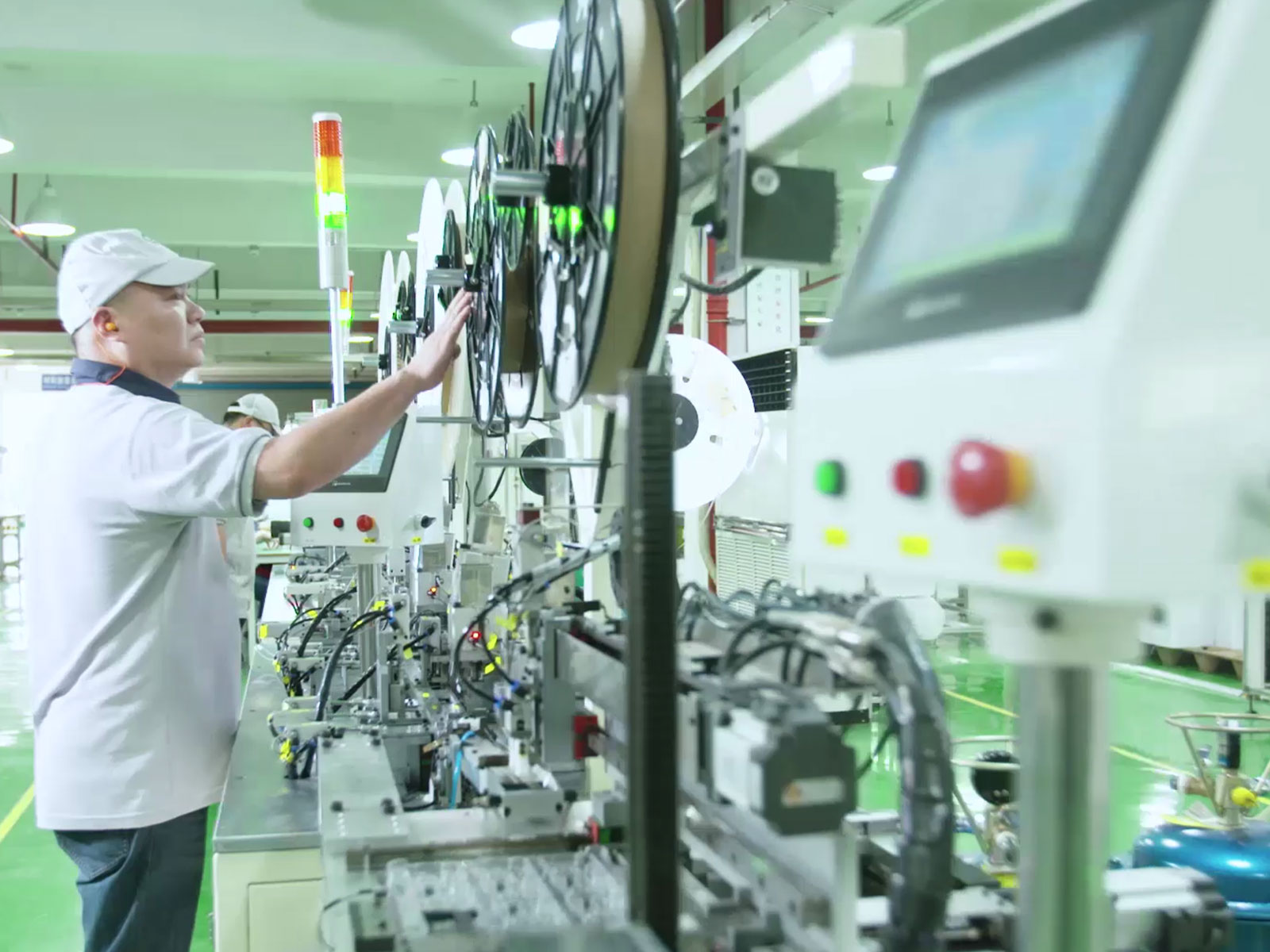

Leoco design and produce cable, connectors and wire harness originally. When we supply you the parts, it comes with all the precision and dedication to meet the demands and operating conditions you require.

BENEFITS OF OEM/ODM

With Leoco, you can be certain of quick response, as less time is needed to identify and produce the part mainly due to our access to the original design. As an OEM, any replacement or maintenance of our production facility will not impact the specification of the products, in fact, most of these scheduled upgrades serve to improve the quality of our products. Our OEM support engineers have access to the same engineering team that design your product, giving you access to a wide variety of technical and engineering support. The value and lifespan of OEM dramatically outperform any others.

Expert Team of Engineers

Offering expertise views on design, our engineers are always ready to listen, develop and deliver reliable solutions to meet your needs.

World-Class Metrology Test Laboratory

Accredited ISO/IEC 17025,offering reliablity,environmental,radio frequency,and material analysis testing.

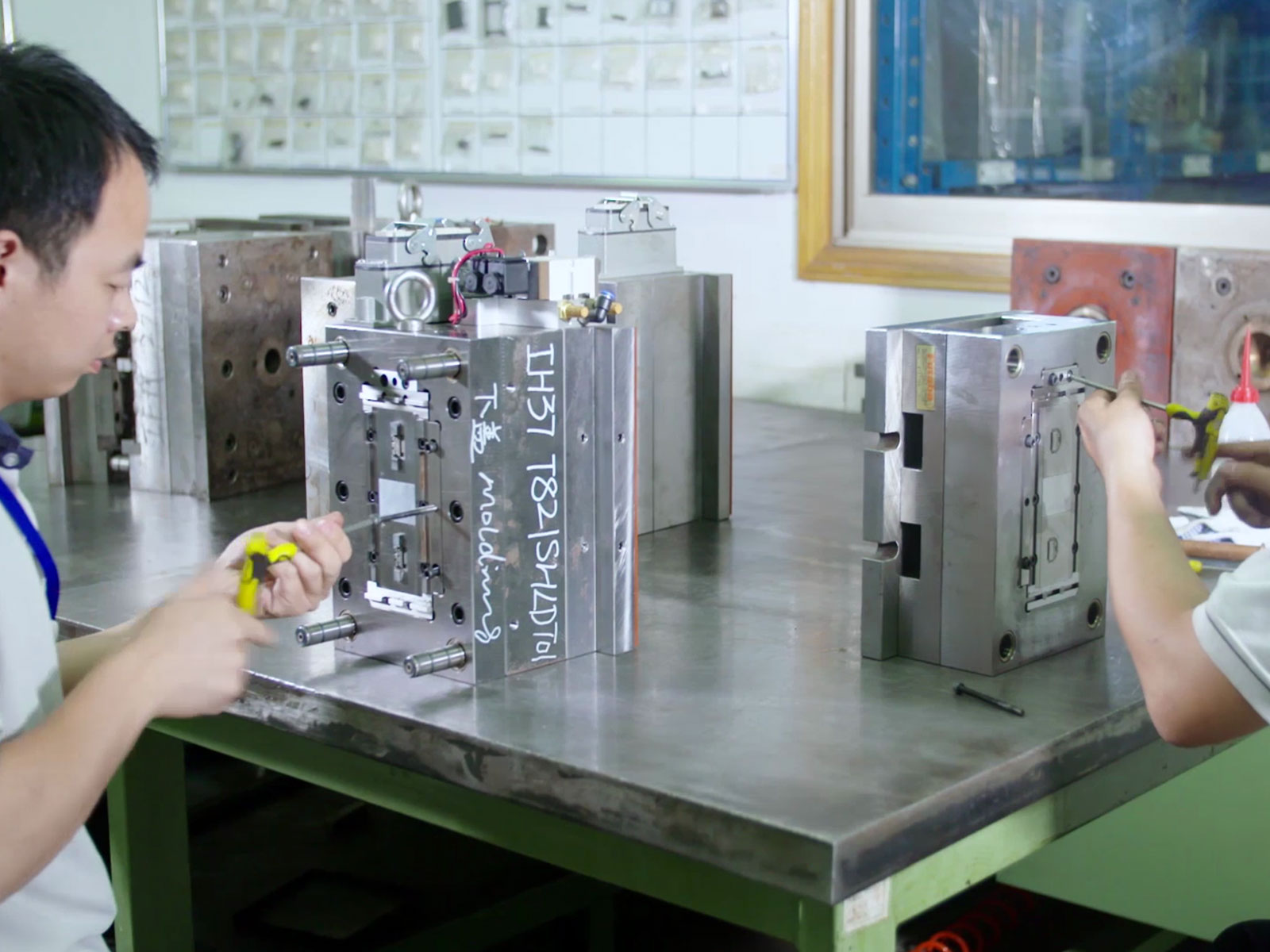

Short Turnaround Time of Prototype Build

In-house tooling workshop enabling inexpensive and quick prototyping process.

Locations on Both Hemispheres

Reach us on both sides of the hemisphere with factories and offices/distributors located in Asia, United States and Europe.

Strong Global Sourcing Power

Raw materials are essential of course and Leoco’s long-term relationship with its material suppliers gives it the edge for cost reduced production therefore passing the savings to our end customers.

Customer / Vendor Partnership

We want our customers to see Leoco as an extensionof their design team. We are focused on our key goals: Listen, Develop, and Build.

Long-term Growth With OEM Customers

Leoco often develop new innovations and improves on technical know-how so as to pass that information back to our customer. These improvements help lay a solid foundation for our customers next generations of products.

Research and Development

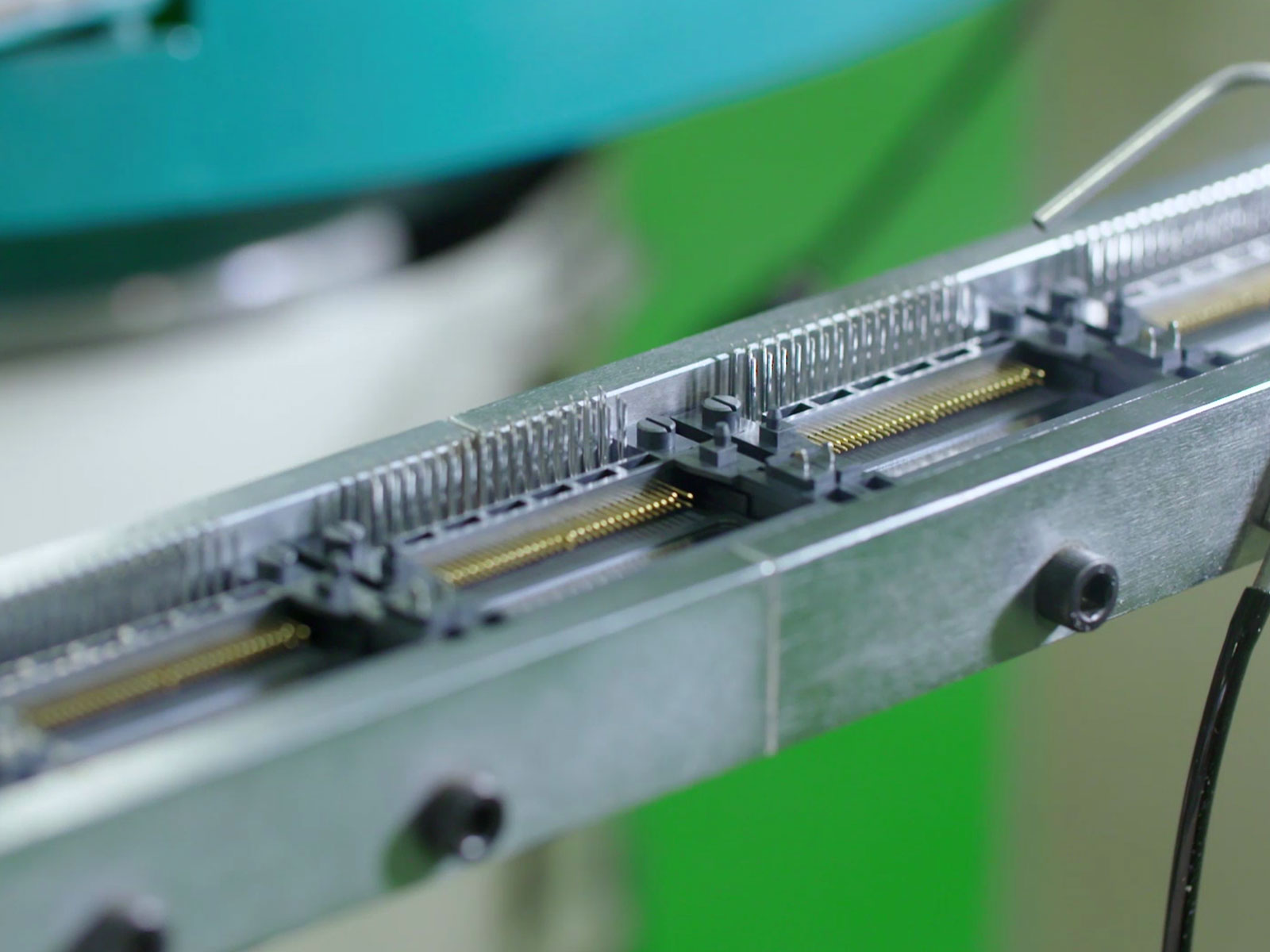

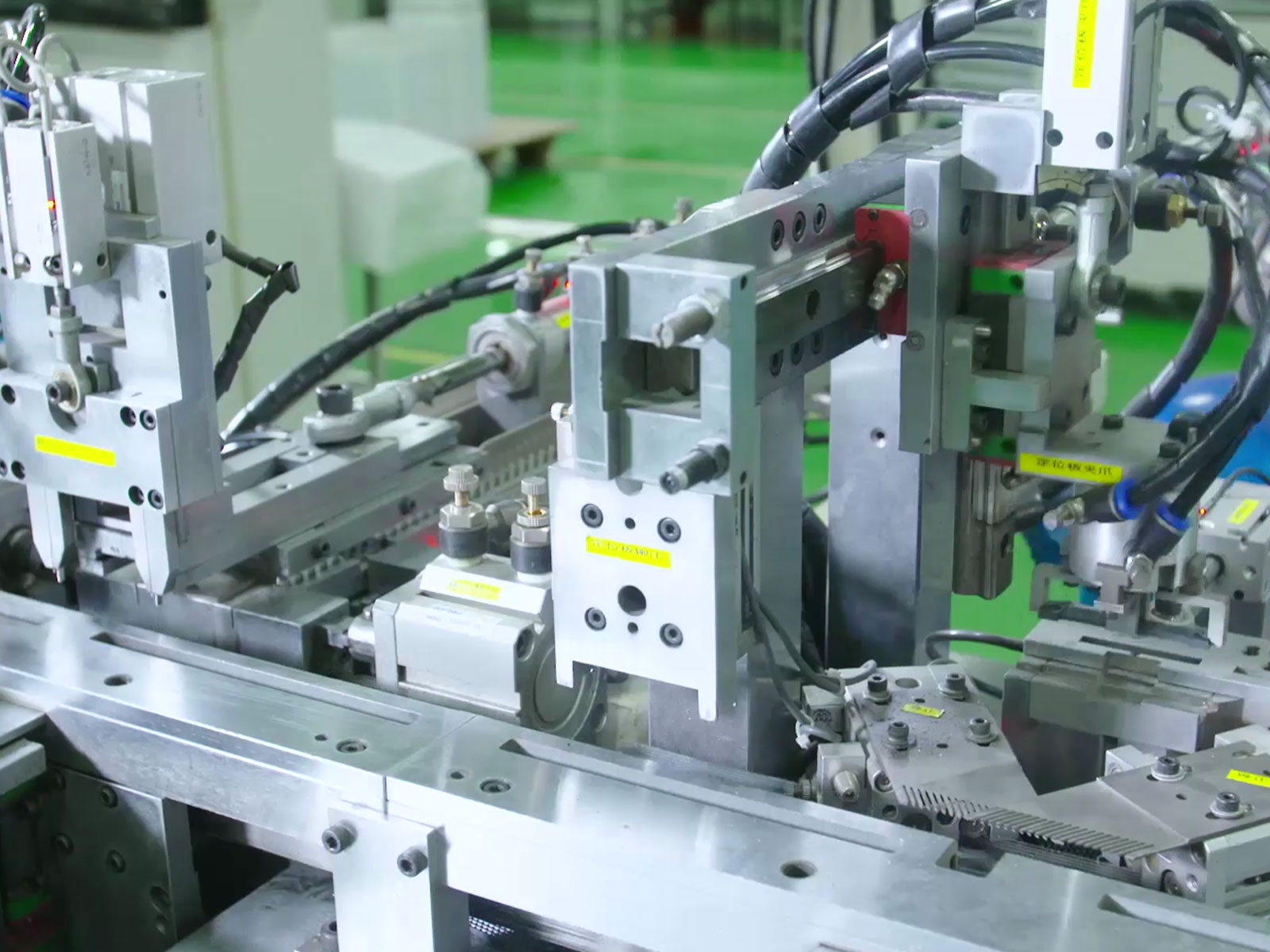

Manufacturing and Assembly

Laboratory Testing

STATE OF THE ART EQUIPMENT

Wire Cut EDM

High-Speed Wire Cut EDM

Low-Speed Wire Cut EDM

Precision Surface Grinder

High-Speed Precision Surface Grinder

Vertical Milling Machine

Low-Speed Verticle Milling

Electric Discharge Machining

Low-Speed Electric Discharge Machining

Plastic Injection

Meiki, Nissei, Jetmaster, Creator, Sodick Plustech, Victor Taichung, Jon Wai, Multiplas

Precision Punch Press

Micron, Dobby, Ming Xu,

Wire Strip and Terminal Crimping

Auto Wire Strip And Terminal Crimping Machine

Wire Cut And Strip Machine

Double Side Auto Wire Cut And Strip Machine

High Speed Auto Wire Cut And Strip Machine

Dedication is the key

At Leoco, our strong track record is built on the foundational beliefs that happy employees bring satisfied customers. With customer satisfaction as our end goal in mind, Leoco Corp always seeks new and innovative ways to achieve our primary mission. Speak to our local customer service officer today to find out more!